Efficient Node Handling

In our previous article, Forward Looking Directions, we emphasized the importance of adaptable buoyancy systems to accelerate node deployment and retrieval. This article focuses on another critical aspect of subsea vehicle-based node operations: the actual handling and transport of nodes by the subsea vehicles to allow an increased number of nodes per dive.

Modern seismic node operations typically involve a subsea vehicle equipped with a skid (or carrier) mounted beneath the vehicle, that stores multiple nodes. This setup enables efficient deployment by minimizing the number of trips the vehicle needs to make to the surface vessel for node replenishment.

Historically, there has been many solutions aimed at streamlining node access and storage, such as carousel-based systems and conveyor systems inside the skid. However, these systems all have limitations. Their mechanical complexity consumes valuable space within the skid, reducing overall node capacity. Additionally, many popular node designs are round or irregularly shaped, making them difficult to stack efficiently.

At Shearwater, we have developed a more compact and reliable solution. Instead of using carousels or conveyors, our system places nodes densely on a tray. A ratchet mechanism moves the nodes forward (for deployment) or backward (for storage) along the tray. This design maximizes stacking efficiency and simplifies mechanical operation. When paired with our proprietary node technology, a standard subsea vehicle can carry over 100 nodes per dive – significantly outperforming legacy systems.

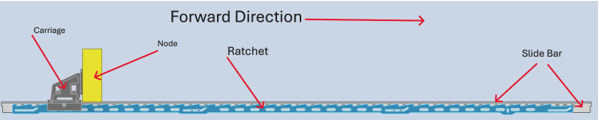

The ratchet mechanism developed by Shearwater, is a mechanical system inside the skid that facilitates efficient movement of nodes between the storage and the front section of the skid where the nodes are retrieved for deployment or placed for recovery (the handling unit). The ratchet mechanism allows motion in one direction, while preventing movement in the opposite direction, a principle that is widely used in machinery and tools, often referred to as magazines.1

During operations, the ratchet’s design enables forward movement during deployment and disengages during its return stroke to allow reverse movement for loading. For loading, nodes are placed into the handling unit manually or e.g. via a manipulator arm. A ratchet bar with teeth and grooves aligns with a selectively engageable carriage in the skid urging the nodes in one direction. When disengaged and moved rearward, the ratchet allows free movement for stacking. An external actuator propels the nodes into the storage part of the skid.

For deployment, the ratchet mechanism allows individual nodes to be fed from storage. The ratchet bar pushes another selectively engageable carriage at the rear of the skid forward, moving the nodes toward the handling unit where the front node is positioned for deployment to the seafloor.

The illustration shows the key features of the ratchet mechanism.

In short, Shearwater’s ratchet system offers the following benefits:

- Mechanically simple – reduces risk of failure.

- Compact design – maximizes space for node storage.

- Optimized for rectangular nodes – enables full utilization of available space.